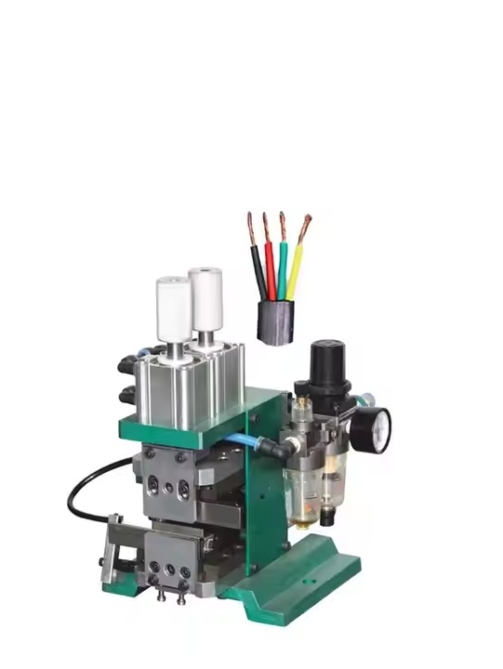

Ultrasonic Welding Machine 2000w,3000w,4000w,6000w, spot welding model, Plastic welding model and as so on

- brand name:-Indoe Enterprises

- model number:-IE-UW20

- Warranty:-1 Year

- Power output:-2000W

- Frequency:-20KHZ

- Voltage:-220V

- Aire source:-0.5kg

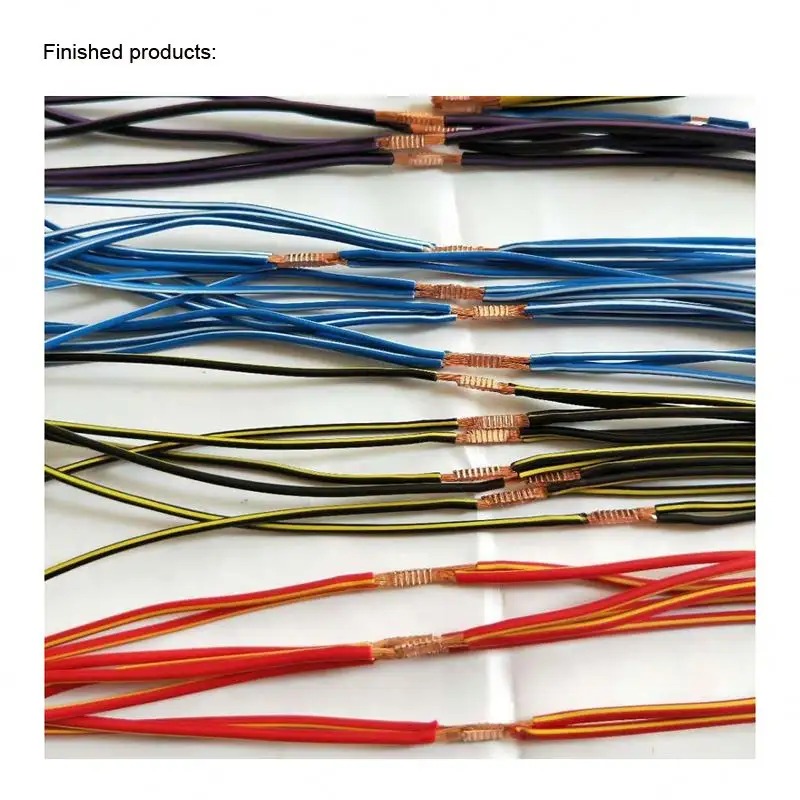

- Welding area:-0.7-12sqmm

- Welding time:-0.2-9S

- Net weight:-38KG

- Dimensions:-460*270*150mm, 380*290*130mm

- Type:-Auto scan frequency

Add to WishlistRemove from Wishlist

Add to Wishlist

Share

- brand name:-Indoe Enterprises

- model number:-IE-UW20

- Warranty:-1 Year

- Power output:-2000W

- Frequency:-20KHZ

- Voltage:-220V

- Aire source:-0.5kg

- Welding area:-0.7-12sqmm

- Welding time:-0.2-9S

- Net weight:-38KG

- Dimensions:-460*270*150mm, 380*290*130mm

- Type:-Auto scan frequency

Cart is empty

Cart is empty